-

All Levels

-

36 Weeks

-

Government / Autodesk Certification

-

Industry Immersion

-

Capstone Projects

Overview

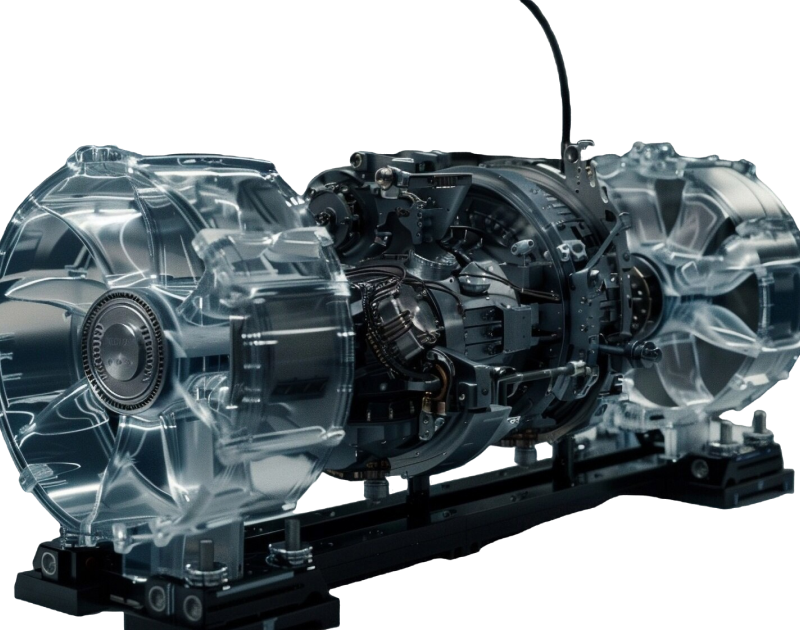

Gain in-depth knowledge of the product development process, from conceptualization to final production. Through a blend of theory and hands-on projects, Product Design and Analysis course provides a deep dive into CAD, prototyping, ergonomics, and design for manufacturing to prepare you for careers in product design.

- Product Designer

- CAD Engineer

- Industrial Designer

- Manufacturing Engineer

Targeted Job

Roles

Training and Methodology

By enrolling in this course, you will gain access to -

Interactive Learning - Engage with practical exercises and projects.

Industry Immersion- Learn from experienced industry professionals.

Capstone Projects - Develop real-world product designs.

Evaluation - We keep tracking student progress through assignments and project.

Why Choose

This

Course?

Enhance Your Skills in Product Design and Analysis

This course is ideal for aspiring product designers looking to build innovative, functional designs that meet market needs. With hands-on experience and expert guidance, you’ll be prepared to excel in various industries.

Register Now-

100% Job Placement Guarantee

Job placement guarantee readiness.

-

Real time projects

Gain practical experience through industry-relevant projects.

-

Reviews and Feedback

Stay on track with regular reviews and personalized feedback.

Skills acquired from this course

-

Expertise in product development, from concept to production

-

Proficiency in CAD for product design

-

Knowledge of materials selection and manufacturing processes

-

Understanding of ergonomics and user-centered design

-

Ability to create and interpret technical drawings and specifications

-

Working effectively in multidisciplinary teams and presenting design ideas clearly

-

Working effectively in multidisciplinary teams and presenting design ideas clearly

Tools & Languages Included In This course

The Course Syllabus

The course covers important topics.

Design Thinking and Concept Development

- Overview of Design Thinking Process

- Rapid Prototyping Methods

- Concept Validation and Iteration

Sketching and Visualization Techniques

- Sketching Fundamentals

- Conceptual Visualization

- CAD-Based Visualization

AutoCAD Software

- Overview of AutoCAD Mechanical

- Setting up a Mechanical Drafting Environment

- Drawing Basics and Modifying Tools

- Introduction to CAD

- 2D Fundamentals

- Preparation of sketches: Lines, Circles, Rectangular etc

- Dimension Style

- Hatch, trim, extend, tables etc

- Layers, Blocks, and Object Management

- Layer Overview, modifying layer attributes

- Editing & modification of sketches

- Scaling objects, views

- Duplication using mirror, copy, pattern etc.

- Creating & editing blocks

- Dimensioning and Detailing Mechanical Parts

- Dimensioning techniques

- Tolerance symbols, Datum, Finish, welding symbols etc

- Isometric Drawing

- Concept

- Snap

- Drawing Isometric objects

- Dimensioning

- AutoCAD 3D

- Introduction to 3D

- Extruding and revolving objects

- UCS concept and it’s use

- Boolean using union, subtract and intersect

- Standard views

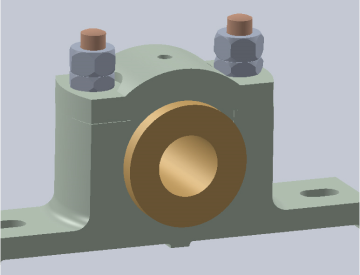

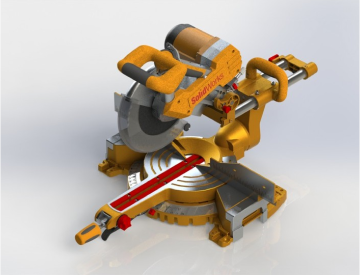

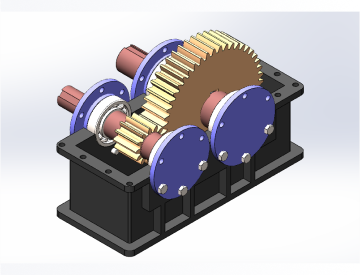

Solidworks Software

- Solid Modeling

- Introduction and Interface

- Sketching and Parametric Solid Models

- Features: Extrude, Revolve, Sweep, Loft

- Part Modifications: Fillet, Chamfer, Shell, Draft, and Patterns

- Assembly Design

- Creating and Managing Assembly Models

- Defining Assembly Constraints

- Surfacing

- Advanced Lofting and Sweeping Techniques

- Surface Modifications and Tweaks

- Sheet Metal

- Bend, Jog, Dimple, and Flange Features

- Creating Flat Patterns and Advanced Features

- Drafting

- Generative Drafting and Views (Exploded, Section, Detail)

- BOM and Annotations

- Animation and Mechanism Design

- Introduction to Product Animation

- Defining Joints and Simulating Product Movements

- Extra Features

- File Management and Blueprint Reading

- Applying Tolerances using IS Standards

UG-NX (Option 1)

- 1) UG-NX

- Introduction to NX Software

- Introduction

- Creating Parts

- Getting parts geometric information

- 3D Part and Assembly Design

- Sketcher mode

- Dimensioning

- Sketch planes

- Extruding, Revolving, Sweep features

- Parametric Modeling

- Modifying parts using History

- Adding Fillet, Chamfer, Shell and Draft

- Creating Patterns

- Assembly Design

- Creating Assembly Model

- Managing Assembly Models

- Defining Assembly constrains

- Generative Drafting

- Plotting various views

- Exploded Views and BOM

- Dimensioning

- Section, Detail and Auxiliary views

- Annotations, Symbols and Datum

- Advance Surfacing

- Creating lofted features

- Creating advance sweep features

- Creating Tweak features

- Modifying features

- Advanced surface modeling

- Sheet Metal

- Introduction to Sheet Metal

- Bend, Jog, Dimple and Flange features

- Hole cut, Lofted Flange features

- Creating Flat Pattern

- Advance Features

- Import, Export using UG NX

- UG NX File Management

- Blue Print Reading

- How to apply Tolerances using IS Standards

- Introduction to NX Software

Ansys (Option 2)

- Introduction to Ansys Software

- Introduction to FEA

- Starting ANSYS Workbench

- Exploring the GUI

- Graphics & Picking

- FEA for Stress and Structural Analysis

- Pre-Processing

- The Database and Files

- 2D Modeling

- Solid Modeling

- How to Import Geometry

- Material Properties

- Real Constants

- Meshing – Multiple Element Attributes, Controlling Mesh Density

- Mapped Meshing, Hex-to-Tetra Meshing, Mesh Extrusion & Sweep Meshing

- Loads and Boundary conditions

- Post-Processing

- Introduction to Solvers

- Read, Write and Plot the Results

- Report Generation

- Animating Result

- File Handling

- Exporting Results to other Post-Processor

- Pre-Processing

- Types of Analysis

- Structural Linear Static, Transient

- Structural Non Linear = Time, Material, Contact and Geometric

- Beam Modeling, Beam Meshing, Beam Properties & Loading

- Symmetric boundary conditions

- Buckling Analysis

- Modal Analysis Procedure

- Harmonic Response Analysis

- Vibration

- Thermal Analysis – Steady State & Transient

- Conduction, convection

- Structural Thermal Analysis (Couple Field)

- Goal Driven Optimization

- Projects

- Capstone Projects / Live Projects

Creo (Option 3)

- Introduction to Creo Software

- Introduction

- Creating Parts

- Getting parts geometric information

- 3D Solid Modeling

- Sketcher mode

- Dimensioning

- Sketch planes

- Extruding, Revolving, Sweep features

- Parametric Modeling

- Modifying parts using History

- Adding Fillet, Chamfer, Shell and Draft

- Creating Patterns

- Assembly Design

- Creating Assembly Model

- Managing Assembly Models

- Defining Assembly constrains

- Drafting

- Generative Drafting

- Plotting various views

- Defining Assembly constrains

- Advance Surfacing

- Creating lofted features

- Creating advance sweep features

- Creating Tweak features

- Modifying features

- Advanced surface modeling

- Sheet Metal

- Introduction to Sheet Metal

- Bend, Jog, Dimple and Flange features

- Hole cut, Lofted Flange features

- Creating Flat Pattern

- Animation

- Introduction to Animation

- Defining various joints

- Animation Setup

- Animation

- Advance Features

- Import, Export using Creo

- Creo version management

- Blue Print Reading

- How to apply Tolerances using IS Standards

- Projects

- Real Life Project / Live Project

Inventor (Option 4)

- Introduction to Autodesk Inventor Software.

- Introduction

- Creating Parts

- Parts geometric information

- 3D Solid Modeling

- Sketcher mode

- Dimensioning

- Sketch planes

- Extruding, Revolving, Sweep. Loft

- I Feature

- Modifying parts using History

- Adding Fillet, Chamfer, Shell and Draft

- Creating Patterns

- Assembly Design

- Creating Assembly Model

- Managing Assembly Models

- Defining Assembly constrains

- Drafting

- Generative Drafting

- Plotting various views

- Exploded Views and BOM

- Dimensioning

- Section, Detail and Auxiliary views

- Annotations, Symbols and Datum

- Sheet Metal

- Introduction to Sheet Metal

- Bend, Jog, Dimple and Flange features

- Hole cut, Lofted Flange features

- Creating Flat Pattern

- Advance Features

- Blue Print Reading

- How to apply Tolerances using IS Standards

- Presentation

- Projects

- Capstone Projects / Live Projects

Want to

experience

excellence?

At Milestone, We are committed to providing a complete education solution in Thane. Access the Free Demo. Get in touch today.

Acces The Free DemoRecruiters looking for Product Design Students

Certification For

This

Course

Receive a recognized certification upon course completion, validating your skills and boosting your career prospects.

Register Now

Capstone Projects In

This Coursework

Our projects are directly aligned with the coursework, ensuring practical application of what you learn. This hands-on approach deepens your understanding and prepares you for real-world challenges.

Get in touch today

Frequently Asked Questions

Find answers to all your questions about our diverse course categories. Discover the range of subjects we offer, and learn how to choose the right courses to match your interests and career goals. Let us guide you in navigating our extensive catalog to find the perfect fit for your educational journey.

-

Who can enroll for this course?

Any person with BE / BTech / Diploma from Mechanical Stream can register for this course.

-

What will be the mode of delivery?

We offer 3 delivery models

1) Classroom

2) Live Online

3) Recorded lectures

Kindly contact us with your requirements. -

Will I receive a certificate after completion of this course?

Yes, you will be getting a certificate from Milestone Institute of Technology, Autodesk, and Government.

-

Does this course align with Industry requirements?

Yes, at MIT we ensure our syllabus and exercises are up to date as per industry requirements. We have used industry examples wherever possible in the course material. Additionally, you can also register your interest in Industry internships opportunities with our placement department.

to a whole new level?